Weighing the Pros and Cons of PTFE/Silicone Septa

Introduction:

PTFE (Polytetrafluoroethylene) and silicone septa are widely used in laboratory settings, particularly in gas chromatography (GC) and high-performance liquid chromatography (HPLC). These septa offer unique advantages and disadvantages that should be considered when selecting the appropriate septa material for specific analytical applications. In this article, we will explore the advantages and disadvantages of PTFE/silicone septa to help researchers and analysts make informed decisions.

Advantages of PTFE/Silicone Septa:

- Chemical Inertness: PTFE and silicone septa exhibit excellent chemical inertness, making them highly suitable for a wide range of applications. They resist reaction with most chemicals, ensuring minimal interference with the sample and maintaining the integrity of the analytical results.

- Good Sealing Properties: PTFE/silicone septa provide reliable sealing, preventing sample evaporation and minimizing the risk of contamination. Their pliable nature allows for a secure seal, ensuring the integrity of the sample during storage and analysis.

- Temperature Resistance: PTFE septa can withstand high temperatures, typically up to 250 to 260 degrees Celsius, making them suitable for applications that require elevated temperature environments. Silicone septa also offer good temperature resistance, generally up to 200 degrees Celsius. This characteristic allows for compatibility with a wide range of analytical techniques and methods.

Disadvantages of PTFE/Silicone Septa:

- Limited Temperature Range: While PTFE and silicone septa offer good temperature resistance, they have a limited temperature range compared to other septa materials. This can be a disadvantage for applications that require extremely high temperatures. In such cases, alternative septa materials should be considered.

- Potential Contamination: PTFE/silicone septa can absorb certain chemicals or volatile organic compounds (VOCs), leading to potential contamination and interference in subsequent analyses. It is crucial to ensure compatibility between the sample matrix and the septa material to minimize the risk of contamination.

- Permeability to Gases: PTFE and silicone septa can exhibit gas permeability, allowing the diffusion of certain gases through the septa. This can affect the accuracy of gas flow control or lead to sample loss when working with volatile samples. It is important to consider the specific requirements of the analytical procedure and select septa materials accordingly.

- Limited Shelf Life: PTFE/silicone septa have a finite shelf life compared to other septa materials. Over time, they may degrade, lose elasticity, and compromise the sealing properties. Regular inspection and replacement of septa are necessary to maintain optimal performance and prevent sample evaporation.

Conclusion:

PTFE/silicone septa offer distinct advantages such as chemical inertness, good sealing properties, and temperature resistance. However, their limited temperature range, potential for contamination, permeability to gases, and limited shelf life should be taken into account when selecting septa materials for specific analytical applications. By carefully considering the pros and cons, researchers and analysts can make informed choices that ensure reliable and accurate results in their laboratory analyses.

Back to List

-

下午4:09Weighing the Pros and Cons of PTFE/Silicone Septa

下午4:09Weighing the Pros and Cons of PTFE/Silicone Septa -

下午4:05Decoding Vial Discard Guidelines: Ensuring Precision in Chromatography

下午4:05Decoding Vial Discard Guidelines: Ensuring Precision in Chromatography -

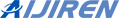

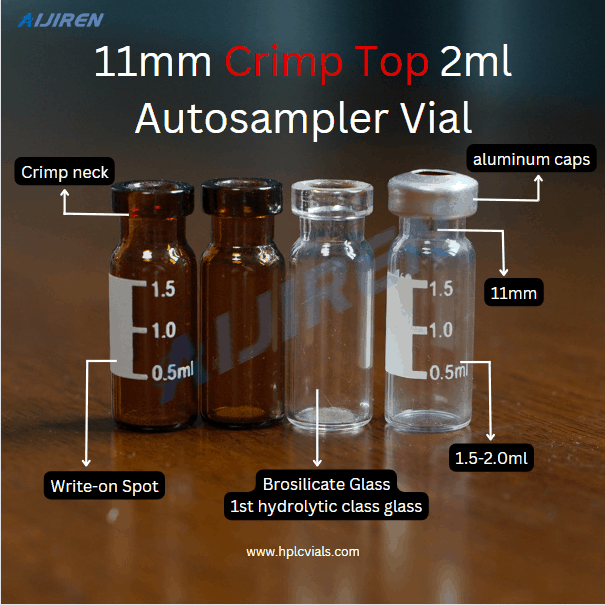

下午5:01Navigating Micro Inserts for HPLC Vials: A Comprehensive Guide

下午5:01Navigating Micro Inserts for HPLC Vials: A Comprehensive Guide -

.jpg) 下午2:02Common faults and solutions of automatic samplers(2)

下午2:02Common faults and solutions of automatic samplers(2) -

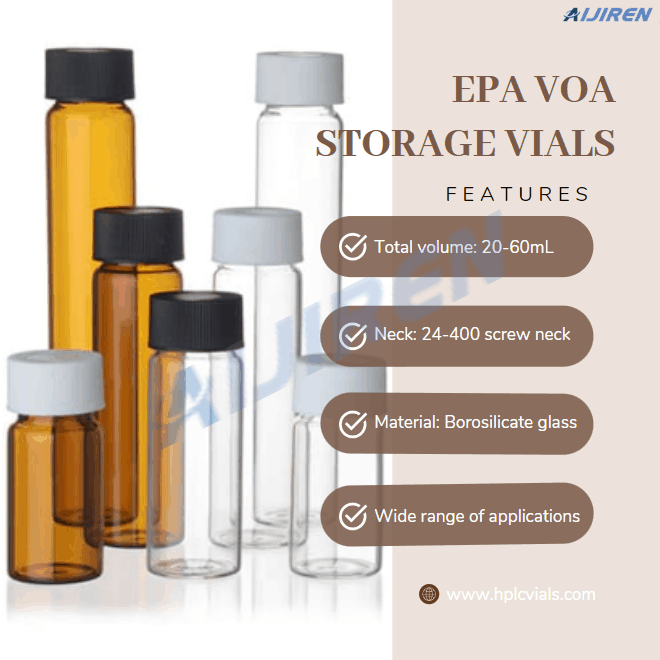

下午5:08Ensuring Sample Integrity: Navigating EPA Storage Vials Stability Guidelines

下午5:08Ensuring Sample Integrity: Navigating EPA Storage Vials Stability Guidelines