Results of Using Re-washed Vials and Closures

When using glass autosampler vials in the laboratory, standard workflows require that vials and closures be considered consumable items and that they are discarded after each use. The use of laboratory dishwashers for the cleaning of laboratory glassware has sometimes been applied to autosampler vials. The cleaned vials are then utilized in the laboratory in hopes of reducing consumable costs.

This note shows that this cleaning is causing both physical damages to the glass vials and is also ineffective at removing contamination from the vial surface. This contamination is unpredictable and produces interference peaks in both LC and GC chromatography applications. Unpredictable contamination can be a major source of unexplained assay failures resulting in the need to repeat the entire analysis of complete sample runs. The experimental work involved an investigation of the physical effects of the washing process followed by the issues of contamination from the previous usage of both the vials and associated septa.

Results of Using Re-washed Vials and Closures

There is a lot of research conducted on this topic. Here are the results of just one of them:

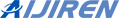

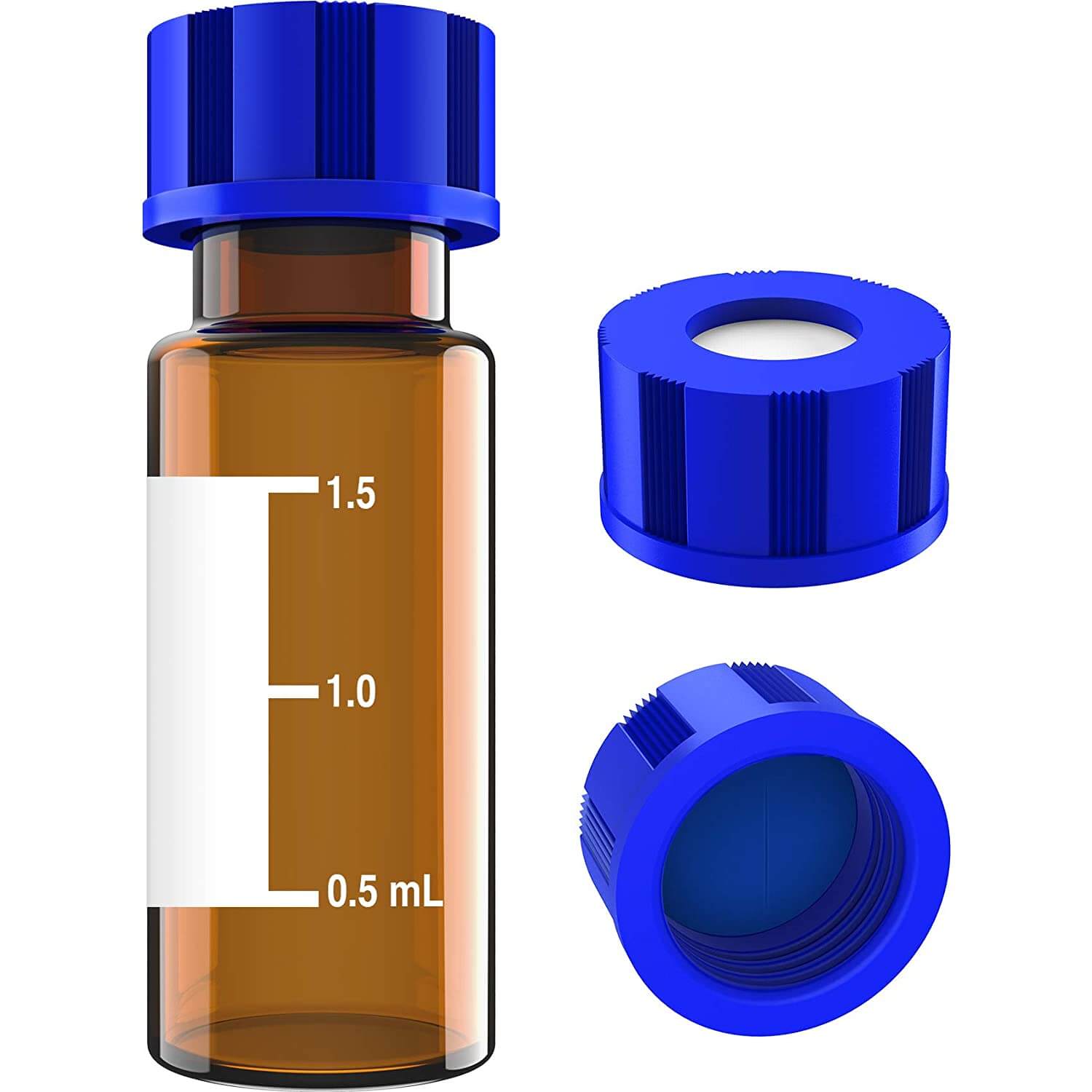

Sample 1: Clear glass vials with re-washed 9 mm screw threads

Sample 2: Amber glass vials with re-washed 9 mm screw threads

Sample 3: New clear glass 9 mm vials (C4000-1W) with PTFE/silicone septa closures (C5000-54B)

Researchers tested these samples and came up with a conclusion.

So, is reusing the vials okay?

The comparison was between the new to the used vial. Here are the results:

1. Scientists used GC and HPLC instruments to compare blank injections from re-washed vials.

2. Extra components are found in the GC-MS blanks in all cases. In the TIC mode, there was interference with standards.

3. Due to an increased incidence of injection liner replacement, GC-Instrumentation downtime has risen.

4. In HPLC, even minor volume injections resulted in the appearance of extra peaks in the UV mode.

5. A complete mass range scan demonstrated the difference between tainted and new vials.

6. When researchers used reused septa, the contamination of the injection was more considerable.

Conclusion

Using reused/re-washed vials and septa might jeopardize optimal chromatographic results. Reused vials and septa can make unpredictable peaks into otherwise repeatable chromatographic techniques. This is a common cause of unexpected assay failures, after which you need to retest whole sample runs. Sometimes even from the very beginning. Any benefits you may get from reusing the vials are not benefits. You spent time on retests and troubleshooting an assay failure that you can’t repeat. Chromatographers that need uncompromised sample integrity should always use brand new vials and septa for each analysis.

Back to List

-

下午4:09Weighing the Pros and Cons of PTFE/Silicone Septa

下午4:09Weighing the Pros and Cons of PTFE/Silicone Septa -

下午4:05Decoding Vial Discard Guidelines: Ensuring Precision in Chromatography

下午4:05Decoding Vial Discard Guidelines: Ensuring Precision in Chromatography -

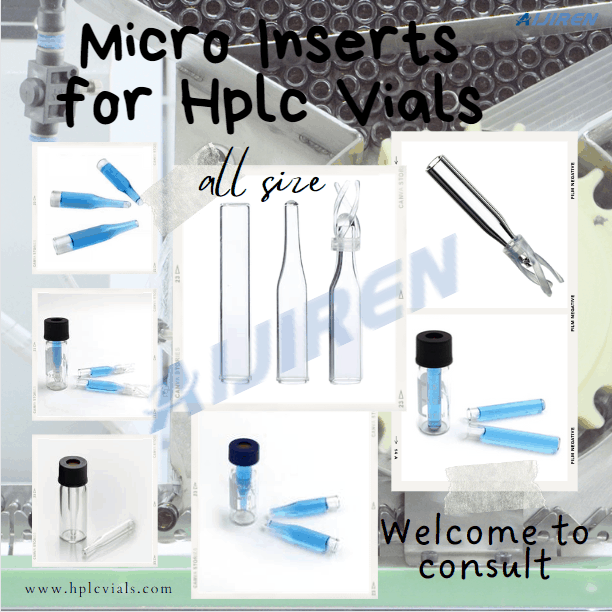

下午5:01Navigating Micro Inserts for HPLC Vials: A Comprehensive Guide

下午5:01Navigating Micro Inserts for HPLC Vials: A Comprehensive Guide -

.jpg) 下午2:02Common faults and solutions of automatic samplers(2)

下午2:02Common faults and solutions of automatic samplers(2) -

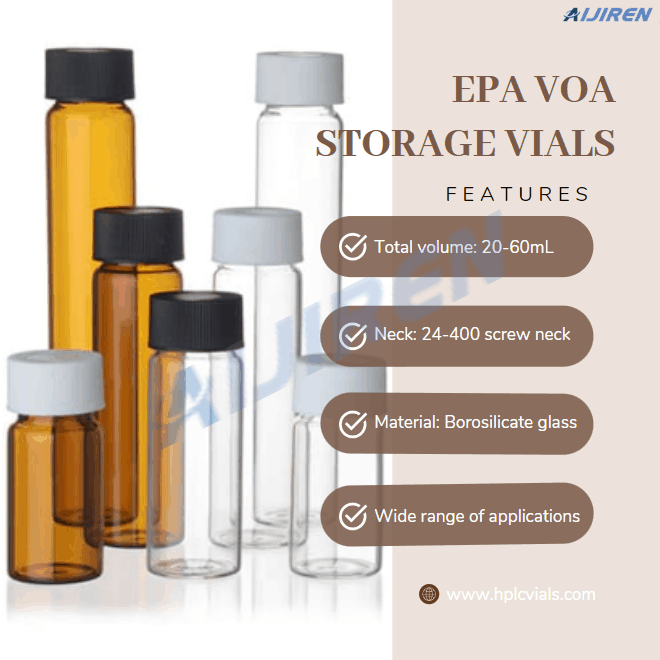

下午5:08Ensuring Sample Integrity: Navigating EPA Storage Vials Stability Guidelines

下午5:08Ensuring Sample Integrity: Navigating EPA Storage Vials Stability Guidelines