A Basic Introduction to Headspace Vials

The sealing property of the headspace vial is better than that of the threaded vial, and the rubber or silica gel has good re-sealing after the puncture, so it is ideal to preserve the reagents. If some of the organic solvents in use will corrode the silicone or rubber bottle pad, the bottle pad with PTFE coating is required, if in use, the reagent is not used up once, but stay in the headspace vial part of the next reuse, then the sample will be volatilized, because the bottle pad with PTFE coating will lose the sealing after a puncture.

Characteristic of Headspace Vial

Aijiren uses PTFE, silicone rubber or ultrapure silica gel as raw material, the product is non-toxic. Unique white silicone spacer, easier to puncture, protect automatic sampler needle, higher purity, and greatly reduce miscellaneous peaks. The adhesive-free process ensures that the two kinds of materials have good chemical inertness, acid resistance, alkali resistance, high-temperature resistance, and anti-adhesion, and the excellent resilience of silicone or silicon layer, which not only ensures the sealing property but also provides softer protection for the needle of the automatic sampler.

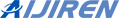

The Aijiren headspace vial has a beveled neck for safe sealing, uniform glass thickness for uniform heating distribution and stability, and a sturdy design that is easy to use. Available in clear and amber USP1 borosilicate glass with screws and crimp top. The round bottom bottle distributes the internal pressure generated under the high temperature of the glass surface, and it is easier to handle the vial being lifted from the tray by the robot arm. The screw-head empty bottle has 18mm rice agate ÇAp, which is suitable for autosampler using magnetic transportation while crimping the top bottle to be used with an aluminum cap.

Specification of Headspace Vial

Headspace vials and caps are used in headspace gas chromatography analysis because of their ability to withstand the pressure from the gas. Aijiren headspace vials come in three basic sizes (6ml headspace vials, 10mL headspace vials and 20mL headspace vials). Both flat bottom and round bottom styles are available for use in a wide variety of headspace instrument platforms.

The material of Headspace Vial

The material of Headspace Vials is low extractable Borosilicate glass with a low expansion rate, high-temperature resistance, high strength, high hardness, high light transmittance, and high chemical stability. Headspace Vials are suitable for headspace analysis of volatile solids and gases. The lid is made of special metal steel, which can be magnetically adsorbed without being easily corroded and changed in shape, while the bottle is designed for the round bottom to have certain automatic injection equipment compatibility while having a flat bottom placement function.

Working Principle of Headspace Vial

Headspace analysis permits the detection of volatile substances in a liquid or solid sample and minimizes column contamination. A small volume of the sample is placed in a vial sealed with a septum and the sample vial is equilibrated at an appropriate elevated temperature.

A headspace sample is usually prepared in a vial containing the sample, the dilution solvent, a matrix modifier and the headspace. Volatile components from complex sample mixtures can be extracted from non-volatile sample components and isolated in the headspace or gas portion of a sample vial. A sample of the gas in the headspace is injected into a GC system for the separation of all of the volatile components.

Adaptation of Headspace Vials

When detecting high boiling points of volatile or semi-volatile mixtures, we need to heat to vaporize the material at the top. In this process, the material in the headspace vial can eventually be measured without touching the liquid in the sample bottle because its liquid (solid or solid-liquid coexistence) sample is in the bottom position. The headspace vial is most suitable for sample analysis of light component volatiles. This measurement technique can effectively analyze the gas in the top space of the liquid sample and be applied to the solid dispersion method.

Back to List

-

下午4:09Weighing the Pros and Cons of PTFE/Silicone Septa

下午4:09Weighing the Pros and Cons of PTFE/Silicone Septa -

下午4:05Decoding Vial Discard Guidelines: Ensuring Precision in Chromatography

下午4:05Decoding Vial Discard Guidelines: Ensuring Precision in Chromatography -

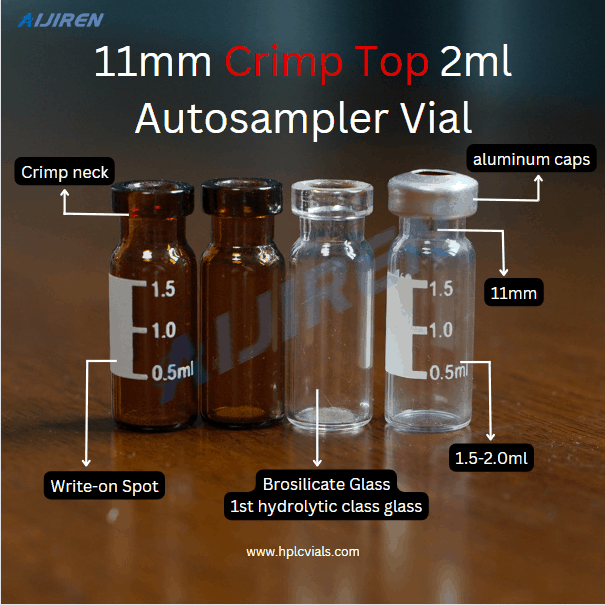

下午5:01Navigating Micro Inserts for HPLC Vials: A Comprehensive Guide

下午5:01Navigating Micro Inserts for HPLC Vials: A Comprehensive Guide -

.jpg) 下午2:02Common faults and solutions of automatic samplers(2)

下午2:02Common faults and solutions of automatic samplers(2) -

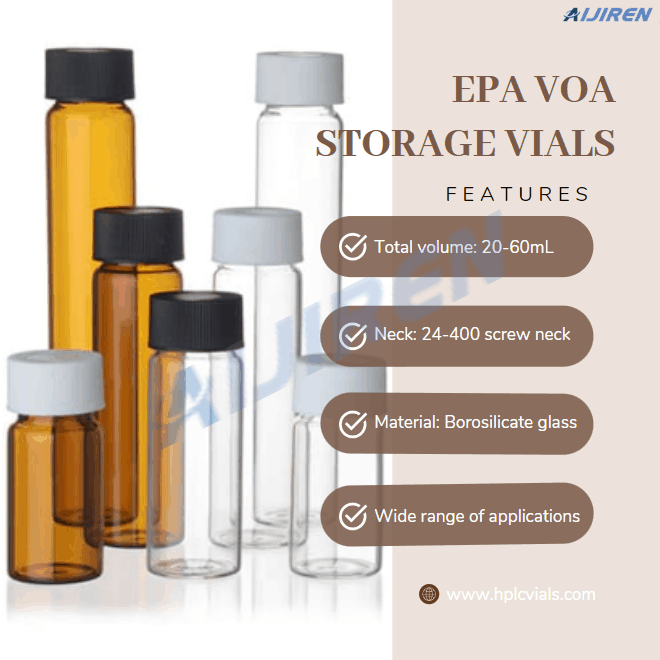

下午5:08Ensuring Sample Integrity: Navigating EPA Storage Vials Stability Guidelines

下午5:08Ensuring Sample Integrity: Navigating EPA Storage Vials Stability Guidelines