How Do You Filter Samples in HPLC?

Sample filtration plays a major role in analytical chemistry. Filtration is a practice where a liquid is freed from suspended solid impurities. The technique is commonly employed in wet chemistry for the separation of precipitates for further quantitative analysis or for the removal of interfering suspensions in spectroscopic studies.

In chromatographic analysis sample filtration before injection becomes all the more important for different reasons. After injection, the sample is carried to the chromatographic column and subsequently to the detector. Any particle impurities if present in the sample will start blocking the chromatographic column leading to irregularities in flow rate which can shift retention times of peaks or complete stoppage of mobile phase flow. Such problems may be overcome with column washing but in severe cases, the expensive column needs to be replaced.

Step 1: Taking the filtration step seriously

A fundamental goal of most laboratories engaged in analytical testing is to develop consistent processes that underpin consistent results – and that require consistent filtering. The selection of a filtration device with the right pore size and retention characteristics helps ensure effective particulate removal, while the choice of appropriate size and design of filter unit can help minimize sample loss. Good filtration also helps to protect the column and potentially extends the lifetime of both the injector and the column.

Step 2: Selecting filters for HPLC

1. Selecting the correct pore size

Most often filters chosen for HPLC have a 0.45µm porosity. Most quality syringe filters are “absolute rated” which means that no particles larger than 0.45um will pass through the filter. This is OK for traditional HPLC columns that have 5µm particle sizes or larger because the gaps between the silica spheres are large enough to allow particles of 0.45µm to pass through easily. However, for smaller particles (e.g. 3µm) and UHPLC columns, the gap between the silica is smaller and it is recommended to use a 0.2µm filter otherwise a build-up of particles can occur and cause a steady blockage over time.

Using a certified filter that is properly tested for every batch will ensure that there is no variation in the filter membranes and that the pore size really is an absolute size, as well as confirm that the membrane is not contributing to peaks in your chromatography. One of the biggest headaches with ‘cheap’ filters is the lack of consistency.

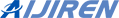

2. The filter membrane

It is important that the filter membrane is suitable for use with the sample and solvent it is dissolved in. A list of filter compatibilities can be helpful to ensure the best selection is made. If you have any questions please feel free to contact us.

Nylon filters have polar surfaces and should not be used with proteins and peptides as they may bind the sample. Low binding membranes such as Regenerated Cellulose (RC) or PVDF should be used instead.

Using the incorrect membrane can result in membrane degradation and elution into the column which is not desirable. Sometimes the incorrect membrane is just hard to use – aqueous samples with PTFE membrane for example. PTFE is naturally hydrophobic and resists water. Using an alternative membrane is usually a lot easier and the results will be just as good or better.

Where high particulate samples are used, a filter membrane with a pre-filter can greatly increase filtration capacity. Pre-filters are generally one or more layers of glass microfibre that will remove the large particles and prevent the main membrane from blocking as quickly.

3. Filter size

The size of the filter will normally have a direct effect on the volume it can filter – the larger the filter, the bigger the surface area and the larger its capacity. However, the actual design of the housing can have a large effect also. Well-designed 25mm filters can actually outperform poorly designed 30mm filters.

Whilst the amount that can be filtered will depend on how many particulates are in the solution, typically 4mm filters can be used to filter up to 5ml, and 13/17mm filters can be used for samples up to about 10ml. These are recommended for many HPLC samples and can save money over larger filters.

If a larger amount of sample is to be filtered then a 25mm or 30mm filter should be used. Many people use this size and still use only a small amount for HPLC analysis.

Step 3: Flawless Filtration

1. Choose filter media type based on consideration of the solvent type.

2. Consider possible interactions between sample analytes of interest and filter media.

3. Ensure appropriate choice of pore size based on the particle size of the analytical column

4. Do not use a filter device larger than required for the sample volume being prepared.

5. For difficult-to-filter samples, consider using a filter device with efficient pre-filters incorporated to increase sample volume handling, rather than using multiple filter units to prepare samples.

6. In general, it is best to filter the sample slowly and gently.

Back to List

-

下午4:09Weighing the Pros and Cons of PTFE/Silicone Septa

下午4:09Weighing the Pros and Cons of PTFE/Silicone Septa -

下午4:05Decoding Vial Discard Guidelines: Ensuring Precision in Chromatography

下午4:05Decoding Vial Discard Guidelines: Ensuring Precision in Chromatography -

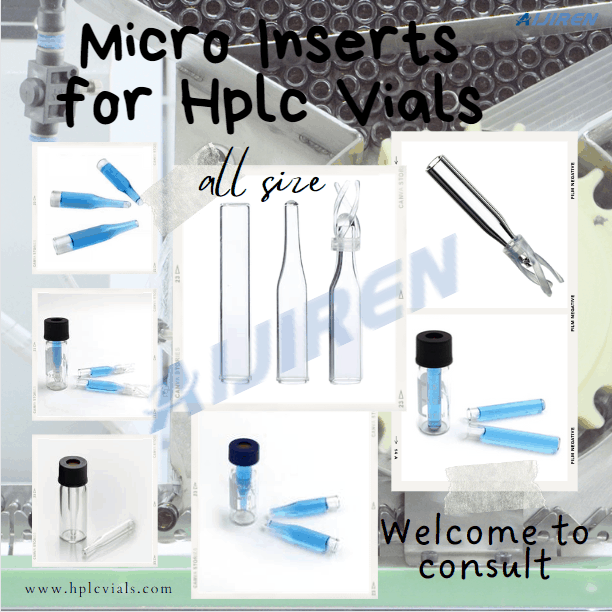

下午5:01Navigating Micro Inserts for HPLC Vials: A Comprehensive Guide

下午5:01Navigating Micro Inserts for HPLC Vials: A Comprehensive Guide -

.jpg) 下午2:02Common faults and solutions of automatic samplers(2)

下午2:02Common faults and solutions of automatic samplers(2) -

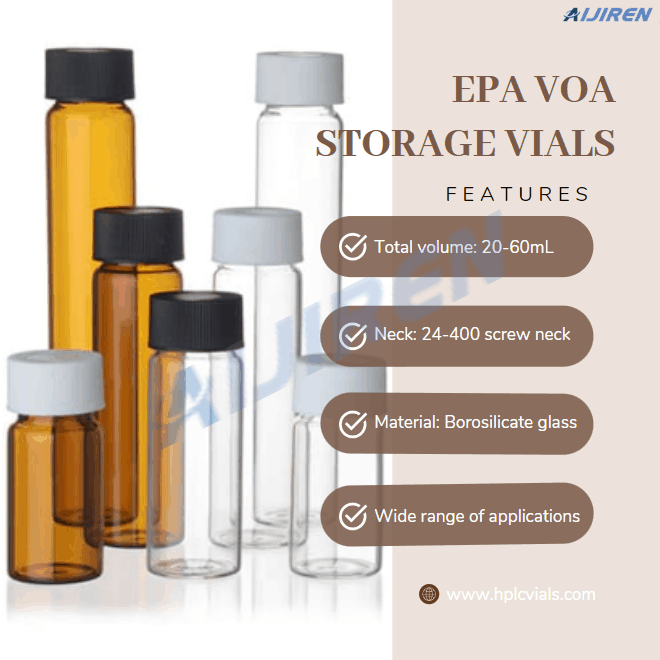

下午5:08Ensuring Sample Integrity: Navigating EPA Storage Vials Stability Guidelines

下午5:08Ensuring Sample Integrity: Navigating EPA Storage Vials Stability Guidelines