How To Choose The Right Small Sample Vial Septa?

By definition, a rubber septum consists of a disk of rubber or similar material used to seal a vial or other device. It is installed along the inside of a cap, which is typically made of metal or plastic. A syringe needle pierces the rubber septa for the purpose of injection and, on withdrawal, the elasticity of the septa ensures that the hole reseals.

So which septa do I need for my autosampler vial? When selecting which septa is right for your experiments, it is important to consider:

Instrument

Each instrument vendor uses different injector needle types and for some instruments, having pre-slit septa, or choosing a material with a lower shore (hardness) value will help reduce the chances of needle issues, such as needle bending.

Compounds of interest

If your compounds are volatile then choosing septa that will provide a tight seal is key to preventing compound loss. Our Advanced Vial Closure System (AVCS) caps remove subjectivity around achieving the optimal seal compression when closing a vial.

Solvents

Some solvents that are commonly used for HPLC, UHPLC, and GC experiments can impact the septa integrity.

Temperature

If you need to place a capped sample vial in a high-temperature environment, then you will need to consider septa materials that are able to withstand high temperatures.

Septa materials & properties

Septa are made from different materials. See below for definitions and uses of different types of septa materials.

Rubber septa

Used primarily for routine analysis in gas chromatography. Offers moderate ability to reseal and good chemical inertness. Not recommended for multiple injections or holding samples for further analysis. PTFE is a protective layer that once broken exposes rubber to chemical attack.

Silicone rubber septa

![]()

High-quality, silicone rubber laminated to PTFE. Use when excellent resealing qualities are a must. Septum resists coring and is recommended when multiple injections are required. Preferred septa for use in liquid chromatography applications.

PTFE and fluoropolymers

Very good chemical resistance and used as a protective layer for less resistant elastomers.

Integral plastic seal

Molded as part of the cap.

Butyl rubber/chlorobutyl rubber

An economical choice for low temperature (< 125°C) or low-pressure applications. Not suitable for alkanes, benzene, chlorinated solvents,l, or cyclohexane without a protective PTFE layer.

Silicone rubber

Excellent septa choice for volatiles with very low background peaks and low permeability. Also ideal for alcohols and aqueous samples. Good resealing characteristics and resistance to coring.

This table provides a summary of the suitability of our septa materials for a variety of applications.

|

PTFE |

PTFE/Silicone | PTFE/Silicone/PTFE |

Butyl |

Natural Rubber |

Silicone |

|

| Temperature range | Up to 260°C | -40°C to 250°C | -40°C to 250°C | -50°C to 150°C | 0°C to 90°C | -40°C to 250°C |

| Multiple injections | No | Yes | Yes | No | No | Yes |

| Price | Very economical | Economical | Most expensive | Economical | Most economical | Very economical |

| Suitable for storage | No | Yes | Yes | No | Yes | Yes |

| Best for | 1. Superior chemical inertness

2. Single injections 3. Short cycle times

|

1. Most common HPLC and GC analysis

2. Not suitable for chlorosilanes |

1. Ultra analysis

2. Repeat injections 3. Internal standards |

1. Organic solvents

2. Acetic acids 3. Impermeable to gases |

1. General GC

2. Limited resealability |

General purpose |

Back to List

-

下午4:09Weighing the Pros and Cons of PTFE/Silicone Septa

下午4:09Weighing the Pros and Cons of PTFE/Silicone Septa -

下午4:05Decoding Vial Discard Guidelines: Ensuring Precision in Chromatography

下午4:05Decoding Vial Discard Guidelines: Ensuring Precision in Chromatography -

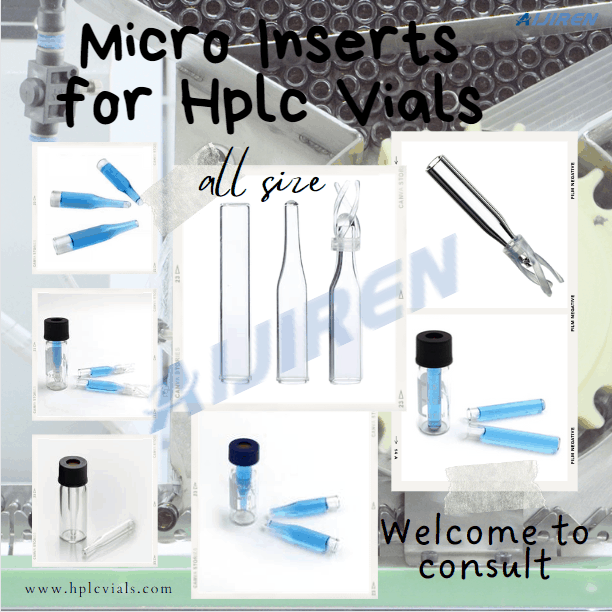

下午5:01Navigating Micro Inserts for HPLC Vials: A Comprehensive Guide

下午5:01Navigating Micro Inserts for HPLC Vials: A Comprehensive Guide -

.jpg) 下午2:02Common faults and solutions of automatic samplers(2)

下午2:02Common faults and solutions of automatic samplers(2) -

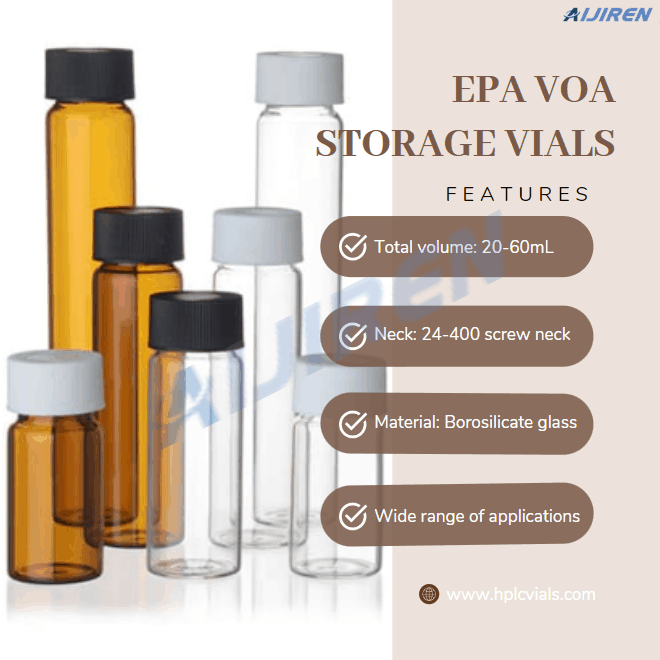

下午5:08Ensuring Sample Integrity: Navigating EPA Storage Vials Stability Guidelines

下午5:08Ensuring Sample Integrity: Navigating EPA Storage Vials Stability Guidelines