How to Choose the Right Chromatography Vial?

Choosing the right vial to store sample mixtures in for high-performance liquid chromatography (HPLC) may seem like an insignificant part of the experimental process, however; having an inappropriate vial for your autosampler machine could run you into serious problems. In this post, I am going to share with you my top tips for selecting the correct vial and how this could save you from disastrous HPLC results!

What are the most common vial styles for chromatography?

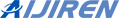

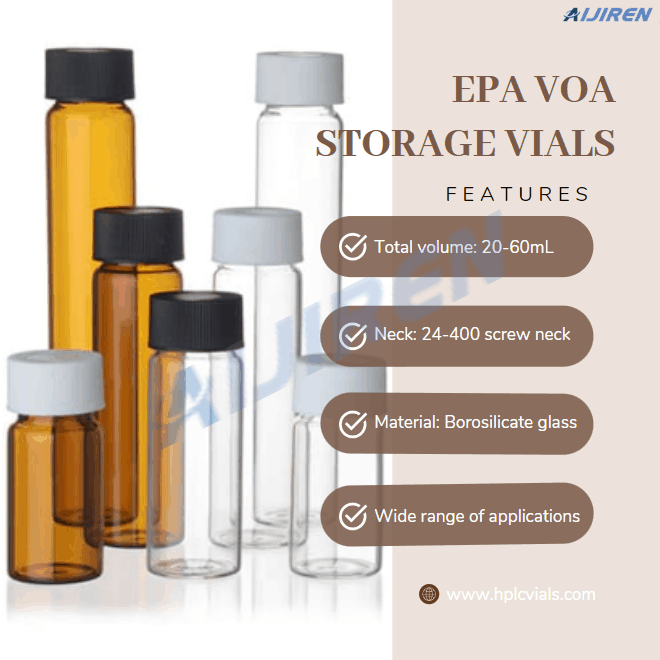

All DWK Life Sciences chromatography vials are made from clear or amber borosilicate glass, which conforms to USP Type I and ASTM E438, Type I, Class B requirements. Two types of applications:

- HPLC: The most common vial sizes for liquid chromatography vials are 12 x 32 mm as well as 15 x 45 mm. 12 x 32 mm vials will also be described as 1.5 mL, 1.8 mL, or 2.0 mL vials.

- GC: Vials for gas chromatography (headspace vials) are available in different sizes and come with a crimp or screw finish. Headspace vials are available with a flat and rounded bottom. The rounded bottom is sturdier and therefore more resistant to the high pressure which builds up inside the vial during the heating process.

What are standard chromatography vials sizes?

Standard chromatography vial sizes include 8 x 40mm, 12 x 32mm, and 15 x 45mm. Robotic Arm Machines (R.A.M.) use a non-standard 9mm vial with a magnetic cap. For autosamplers, choose a vial designed for that specific brand.

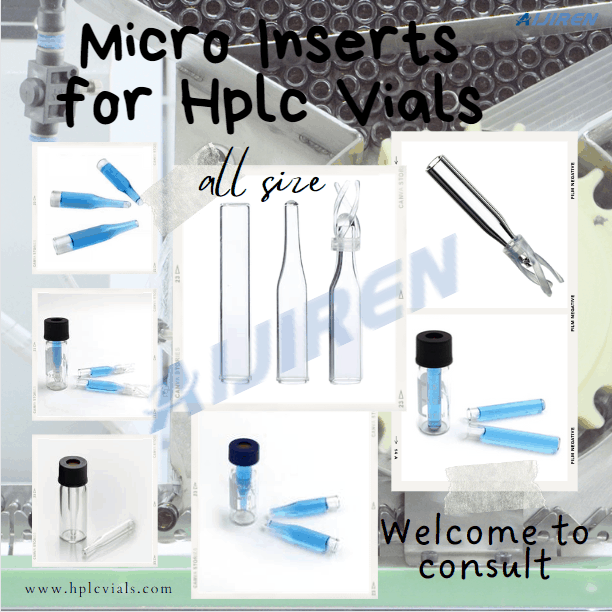

Inserts can be used to decrease the capacity of the vial while maintaining the exterior dimensions. They are useful for smaller samples to ensure the correct amount of sample is aspirated from the vial. Inserts may be flat bottomed, conical (often with a plastic spring at the bottom), or pre-fused into the vial itself (sometimes called a micro vial). Make sure the insert that you choose will fit within the dimensions of the vile you have selected.

What is HPLC chromatography?

HPLC stands for high-performance liquid chromatography. At its core, HPLC is an analysis process that separates, identifies, and quantifies various components in a singular mixture.

These days, HPLC is being used more and more to work out the various levels of cholesterol and other sterol substances in food and tissue extracts. That being said, it is used predominantly to analyze antibiotics and medical samples. It’s often compared to other conventional microbiological assays but is superior because of its sensitivity, analysis time, and specificity.

What are chromatography vials made for?

Chromatography vials are usually made of clear glass or plastic. Amber-tinted vials help protect the contents from exposure to light. Glass is preferred for its inertness, but polymers may be needed for ion chromatography to eliminate interferences. Common plastic options include:

Polypropylene (PP): Translucent and heat-resistant to 135℃

Polymethylpentene (PMP): Transparent and heat resistant to 175℃

How to choose the right vials?

While we may consider the vial a simple, temporary container, choosing the correct vial will go a long way to ensuring the results are as accurate as possible. Sites like www.hplcvials.com make it easy to understand what you need and how to find it efficiently.

That being said, there are some key things to consider:

-

Size

Vials come in a variety of sizes to suit many needs. Standard sizes include 12x32mm (2mL), 15x45mm (4mL) and 8x40mm (1mL). Users may also choose vials with a normal (4 mm) mouth opening or a wide (6 mm) mouth opening depending upon the cap type to be chosen. Important also is whether your sample is handled via a Robotic Arm Machine (R.A.M.). These vials must use a nonstandard 9 mm vial cap size. Samples to be examined are sometimes rather small, necessitating the use of Limited Volume Vials (LVVs). Depending on use or preference, this type of vial can be plastic, glass, or both (i.e. plastic but the sample insert is glass) and the insert can be attached or removable.

-

Color

Both glass and plastic vials can be either clear or amber in color. The reason for this concerns the protection of the vial’s contents from UV light, which may damage certain chemicals. Easily damaged chemicals are best suited for amber vials, while clear vials provide the best visibility of chemicals. Glass amber vials are made from 33 expansion glass, which can be heated at higher temperatures during the manufacturing process (1,200°C) while clear glass vials are made from 51 expansion glass (heated at 1,00°C during manufacturing).

-

Material

Glass Autosampler Vials

The most common type of Autosampler vial is the Type 1 Borosilicate Glass, which represents the least reactive glass. Type 1 glass has the least pH shift (lowest leaching characteristics) and a Coefficient of Expansion = 33 for Clear and 51 for Amber.

Plastic Autosampler Vials

Plastic vials are an economical option when you need a limited volume vial. Plastic Vials are most often Polypropylene (PP). Polypropylene Vials are compatible with Acetone, Ethyl Acetate, Methanol, Isobutyl alcohol, methanol, and methyl ethyl ketone. They are incompatible with cyclohexane, ethers, dichlorobenzene, pentanes, methylene chloride, and trichlorobenzene. -

Closure Style

Screw Thread Vials

Screw thread vials are typically used for HPLC and LCMS analysis. Screw thread vials do not require additional tools for attaching the cap, nor for removing the cap.

Crimp Vials

Crimp Vials are commonly used as GC Vial for gas chromatography analysis. Crimp Vials are the gold standard when concerned with sample evaporation. Crimp Vials are also required when chain-of-custody or tamper-proof closures are required. When using crimp vials, we recommend the electronic vial crimper for ergonomic crimping of your GC vials.

Snap Top Vials

Snap-Top Vials are convenient for lab technicians and are sometimes preferred over screw thread vials. Snap-Top vials are typically used for HPLC or LCMS analysis, and the closure is simply pressed down on the vial to make the seal.

-

Compatibility

If you are using an autosampler, be sure to confirm compatibility with the manufacturer’s requirements before referencing this guide. There are hundreds of models of autosamplers available, each with its own purpose and specifications for use. Some use robotic arms to pick up the vial while others rotate the tray and align the sampling needle to the vial.

Most autosamplers require a very specific vial size and closure type for proper usage. If the wrong type of vial is used with your autosampler, this could result in mechanical damage.

-

Quality

Oftentimes, you are dealing with tiny amounts of a sample that needs to be measured as accurately as possible. Additionally, you may have strict requirements for inertness and cleanliness.

Regardless, it is critical to minimize the risk of contaminating or comprising the sample. Ensure the products you purchase have a quality certification such as ISO9001:2015 and validate the processes for which the vials and any related accessories such as septa or inserts are produced.

Check to ensure the vial manufacturer has policies for cleanroom production and R&D/Quality control measures in place. Experienced technicians should be auditing products to ensure the highest possible quality. -

Cap and Septa

- Proper cap and septum selection are critical to preventing contamination and avoiding damage to the needle and instrument. There are several types of caps and septa available including:

1. Screw top caps – open/closed option

2. Short thread caps – open/closed plus magnetic option

3. Snap ring caps

4. Push-on caps

5. Crimp top caps – center hole option

6. Headspace caps – pressure release option

Caps are typically either made from aluminum for crimp top vials or plastic for non-crimp top vials. There is usually a septum lining the inside of the cap with PTFE lamination that faces the sample. Septa are also sold separately for insertion into caps.

Chemical compatibility can vary depending on the concentration of the solvent, temperature, molecular weight of the solvent, and other factors. Therefore it is always recommended you try a variety of septa to determine the best one for analysis. -

Micro-inserts

Micro-inserts are designed to maximize sample recovery and are either integrated within the vial or sold separately for a removable option. The insert reduces the surface area inside the vial making it easier to recover the sample.

There are several types of inserts available including:

1. Cone-shaped inserts

2. Inserts with springs – top or bottom options

3. Shell-style inserts

Micro-inserts are typically used for micro-volume sampling for smaller sample sizes. If you are dealing with an inert material such as a PH-sensitive or biological sample, a plastic polypropylene insert is recommended.

-

Labeling

Many vials come with writing areas for easy labeling. Consider this writing patch option if you don’t have an automatic or manual label printer. Either way, you’ll want to plan a system for labeling prior to sampling so you can easily find samples and know exactly what they are.

-

Storage Methods

The most common method for storing vials is utilizing a tube or vial rack. You will want to make sure the rack you purchase will fit the vial size you are trying to store. Additionally, several vial racks are compatible with autosampler usage. Check with the autosampler manufacturer to confirm.

In Conclusion

So, as you may have gathered, selecting the correct vial for HPLC is not always a straightforward task however, I hope these recommendations serve as a good starting point.

If you are looking for a specific vial, please reach out to us at www.hplcvials.com and we will assist you.

Back to List

-

下午4:09Weighing the Pros and Cons of PTFE/Silicone Septa

下午4:09Weighing the Pros and Cons of PTFE/Silicone Septa -

下午4:05Decoding Vial Discard Guidelines: Ensuring Precision in Chromatography

下午4:05Decoding Vial Discard Guidelines: Ensuring Precision in Chromatography -

下午5:01Navigating Micro Inserts for HPLC Vials: A Comprehensive Guide

下午5:01Navigating Micro Inserts for HPLC Vials: A Comprehensive Guide -

.jpg) 下午2:02Common faults and solutions of automatic samplers(2)

下午2:02Common faults and solutions of automatic samplers(2) -

下午5:08Ensuring Sample Integrity: Navigating EPA Storage Vials Stability Guidelines

下午5:08Ensuring Sample Integrity: Navigating EPA Storage Vials Stability Guidelines